I have been working on a blown head gasket replacement for this engine. (Mysteriously the head & block were not warped – so I replaced thermostat & water pump hoping that an overheat caused it to blow)

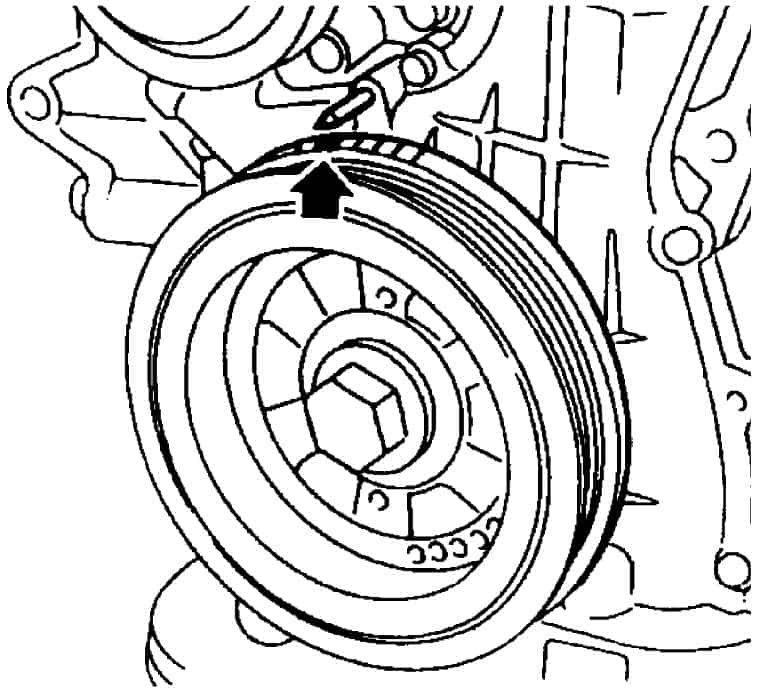

I have gotten to the rebuild & put the cams back in. When I went to turn the engine over to check for interference with the pistons & valves it does get stuck at one point. The last idiot tried to do some work on the engine & had removed the crank pulley. It seems to have all gone back together with the timing marks on the cam gears matching the chain marks.

I have no idea how to move on. Any thoughts?

You stated that something is getting stuck. This sounds like something is hitting internally. Taking it back apart would be the next step.I am thinking you may need to check for a bent valve or just re-check timing.

Make sure to follow the rule of turning the engine over several times to check your timing is good before assembling the rest of the engine.

Select your Vehicle Repair Manual to get the full Instructions including images, wiring diagrams and more.