, had a new timing belt, installed, 1 year ago, with , all belts, , water pump ect. on my 2009 KIA Rio, , just 4 weeks after that , started hearing a low sounding ticking noise, always suspected the timing belt tensioner, , , near the spring, cause mechanic told me, , there was like a smalll screw , near the adjuster spring on , belt tensioner he said was missing, , , , took to another mechanic twice to have he hear and evaluate, the ticking sound did not produce at that time., , long story short, is this, the mechanic who did the timing belt and all, should have , , done the tensioner, and or screwed it up, car wont start, , , another mech is in process, of diagnosing and has replaced cam sensor and all 4 coil packs and spark plugs, , , , he also mentioned, he somehow bypassed, , , and started the car once, the other day, ,so, if timing belt, was broke, he could not have done this., , i hope and pray, the mechanic , who replaced, the timing belt, , 1 year ago, did not cause catastrophic, damage to my engine, , , , i keep all reciepts records, and never went back to him, because, , , , and also because he replaced all my coolant hoses, and , never tightened the belt clamps down, , , and had to go several times , , to reg. mechanic , , , none where tightened., , i pray he didn’t, cause, , , , due to the belt tensioner , missing part crap. where he said, he put another small screw in there, , but wasn’t, i just know a factory screw, so, jimmy rigged it? something makeshift? have read where a bad, or failing belt tensioner, can tick, while idle , ect. and was trying several times, , with my reg. mechanic to address this issue, , everyone let me down, , anyhow so far, the new mechanic, hasn’t done, all the tests yet, as to why car still wont start, but, if he , bypassed, , , with a bad cam sensor, , and bad coil packs ect. the other day, with some tool he had, and car started once, i have to believe, it was not a broken timing chain, hope pray, or the car would not have started, at all, correct?, hope and pray its something else, , any info. you have, thank you.,

You are correct in your thinking that if the timing belt/chain is broken the engine will not start.

TIMING & BALANCE SHAFT BELTS

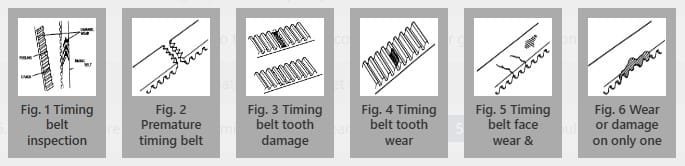

Inspect the timing and balance shaft belts for oil or grease contamination. Also look for damage, wear, peeling, cracks or hardening, Fig. 1. If the belt is found to be contaminated with grease or oil or damaged, it should be replaced.

If there is any damage to the belt, proceed as follows:

- If there is premature parting, Fig. 2, inspect:

a. For improper installation, including excessive tension and crimping due to improper handling.

b. The timing belt cover gasket for damage or improper installation.

c. The belt drive path for foreign objects. - If the timing belt teeth are sheared, Fig. 3, inspect for:

a. Seized drive components.

b. Low installation tension. - If the timing belt teeth are worn, inspect for:

a. Worn pulley.

b. Improper installation tension. - If there is wear on the land between the teeth, Fig. 4, inspect for:

a. Excessive installation tension.

b. Rough sprockets or pulleys.

c. Damage to the timing belt cover or improper gasket installation.

d. Foreign material on sprocket teeth. - If there is noticeable timing belt face wear or cracks, Fig. 5, inspect the pulleys for nicks.

- If the timing belt back is cracked, inspect for high or low temperatures.

- If there is wear or damage on only one edge of the timing belt, Fig. 6, inspect for:

a. Flange damage.

b. Improper component alignment. - If the timing belt is noisy, inspect for:

a. High or low installation tension.

b. Misalignment of belt or drive components.

c. Flange damage.

AUTOMATIC BELT TENSIONER

The automatic timing belt tensioner is used to maintain proper timing belt tension. Inspection procedures are located in the vehicle manufacturers’ sections under “Timing Belt, Replace.”

BELT TENSIONER SPRING

Inspect the timing belt tensioner spring for abnormal shape and weak retraction. If the spring is found to be weak or damaged it should be replaced.

TIMING BELT, REPLACE

These engines are classified as an Interference engine. If the timing belt breaks or jumps timing, a piston may contact an open valve. Piston to valve contact may cause damage to the valve, piston and other engine components. In some cases valve to valve contact may be experienced when the timing belt breaks or jumps timing. To avoid belt breakage, replace the timing belt as recommended by the vehicle manufacturer timing belt replacement interval.

With the timing belt removed, avoid turning the camshaft or crankshaft. If movement is required, exercise extreme caution to avoid valve damage caused by piston contact.

- Record the radio station presets, then disconnect and isolate the battery ground cable.

- Remove the engine cover attaching screws, then the cover.

- Loosen the righthand front wheel lugnuts.

- Raise and support the vehicle with jack stands, then remove the right front wheel and tire assembly.

- Remove the two bolts securing the righthand side cover, then the cover.

- Loosen, but do not remove, the water pump pulley attaching bolts.

- Remove the alternator drive belt.

- Remove the A/C compressor drive belt.

- Remove the power steering pump drive belt.

- Remove the water pump pulley attaching bolts, then the pulley.

- Remove the four upper timing belt cover attaching screws, then the cover, Fig. 1.

- Align the crankshaft pulley and camshaft sprocket timing marks, Figs. 2 and 3.

- Remove the crankshaft pulley retaining bolt, then the pulley.

- Remove the crankshaft flange.

- Remove the four timing belt lower cover attaching screws, then the cover.

- Loosen the timing belt tensioner mounting bolts, then move the tensioner toward the water pump. Tighten the tensioner bolts to hold the tensioner in position.

- Remove the timing belt from the sprockets and the tensioner pulley.

- Ensure the camshaft and crankshaft sprocket timing marks are aligned, Figs. 3 and 4.

- Install the new timing belt over the crankshaft sprocket, idler pulley, camshaft sprocket and the tensioner pulley. Ensure there is no belt looseness between any components.

- Loosen the timing belt tensioner mounting bolts and allow the belt to tension.

- After checking timing belt alignment, torque the timing belt tensioner mounting bolts to 14.5-19.5 ft. lbs.

- Rotate the crankshaft clockwise two revolutions.

- Align the crankshaft and camshaft timing marks, Figs. 3 and 4. If the timing marks do not align, the timing belt must be removed and re-installed.

- Verify that when the tensioner and tension side of the timing belt are pushed in horizontally with a force of approximately 11 lbs., the timing belt cog end is approximately 1/2 of the tensioner mounting bolt head radius (across flats) away from the bolt center, Fig. 5.

- Align the crankshaft and camshaft timing marks, Figs. 3 and 4. If the timing marks do not align, the timing belt must be removed and re-installed.

- Install the lower belt cover. Torque the cover attaching bolts to 70-86 inch lbs.

- Install the crankshaft flange.

- Install the crankshaft pulley, washer and bolt. Ensure the crankshaft sprocket pin engages the small hole in the pulley. Torque the bolt to 101-109 ft. lbs.

- Install the upper belt cover. Torque the cover attaching bolts to 70-86 inch lbs.

- Install the water pump pulley. Torque the bolts to 9-13 ft. lbs.

- Install the power steering, A/C compressor and alternator drive belts.

- Install the righthand side cover, then the wheel and tire assembly.

- Lower the vehicle and tighten the lugnuts

- Install the engine cover and torque the attaching screws to 35-52 inch lbs.

- Connect the battery ground cable.

- Reset the radio station presets and the clock.