Car will not go into gear, I have changed the pilot bearing, clutch, pressure plate, slave cylinder, and master cylinder. What can be the issue?

You will want to perform a quick test if you haven’t done so already. With the engine off, see if you can change gears. If you can the transmission internal components are good. Now place the vehicle in gear and start the vehicle. Is the vehicle trying to pull with the clutch pedal on the floor? If yes, there is air in the hydraulic clutch system. Does the the engine rev and car doesn’t want to move? That is a sign of a worn clutch and or pressure plate.

If you are installing an aftermarket clutch setup, refer to the manufacturers installation instructions.

In most of these cases the problem is not being able to bleed the air from the clutch master/slave cylinders. I have found that buying a sealed replacement from the dealership is the fastest and cheapest way to fix the problem. I have not been successful at bleeding air once installed.

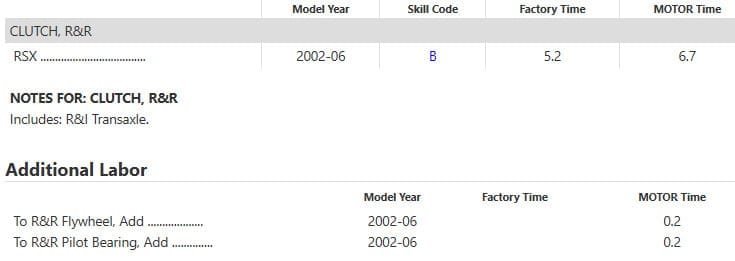

Labor Time Clutch Replacement

Clutch Master Cylinder, Overhaul

Dismantle and inspect inside cylinder before purchasing rebuild kit. If pitting or scoring exist replace clutch master cylinder.

- Drain clutch hydraulic system.

- Remove clutch master cylinder from vehicle.

- Remove hydraulic fluid reservoir from master cylinder if equipped.

- Pull back rubber boot. There is no need to unscrew clevis from push rod. This saves you from having to adjust linkage.

- Remove snap ring holding push rod/washer in place using a suitable set of snap ring pliers.

- Pull out piston/spring assembly. You may have to use compressed air to assist in removal.

- Clean inside and outside of cylinder with denatured alcohol or fresh brake fluid. If you notice any pits or scrapes in cylinder, you will need to replace it with a new one.

- Lubricate new piston O-rings, with suitable lithium base grease.

- Slide assembly into cylinder.

- Pack end of piston, where push rod will rest and pivot, with suitable grease.

- Attach snap ring in place using snap ring pliers.

- Replace rubber boot.

- Replace reservoir with new copper crush washers, if equipped.

- Reverse procedure to install, note following:

a.Fill and bleed clutch system.

b.Inspect for hydraulic fluid leaks.

c.Ensure clutch operates correctly.