How long should my spark plugs last?

A set of spark plugs usually requires replacement every 20,000-30,000 miles (32,180-48,270 Km) for most pre-1996 cars with electronic ignition systems, or every 15,000 miles (24,135 Km) on turbocharged vehicles with electronic ignition, depending on your style of driving. 1996 and newer require spark plugs around 80,000-100,000 miles.

Typical Ignition System (DIS) Distributorless Ignition System Spark Plugs Coil Distributor Testing with a Multi-meter

In normal operation, plug gap increases about 0.001 in. (0.0254mm) for every 1,000-2,500 miles (1,609-4,023 Km). As the gap increases, the plug's voltage requirement also increases. It requires a greater voltage to jump the wider gap and about two to three times as much voltage to fire a plug at high speeds than at idle. Therefore, it is extremely important to check and/or regap each spark plug between replacements. While the need for such maintenance will be affected by your driving conditions, as well as the condition of your vehicle's ignition and fuel systems, checking the condition of your vehicle's spark plugs between tune-ups is a good practice. For vehicles regularly subjected to severe service, such as extensive idling or frequent short trips of 10 miles (16 Km) or less, it is recommended that the spark plugs be checked and regapped every 6,000 miles (9,654 Km).

When you are removing spark plugs, you should work on one at a time. Do not start by removing the plug wires (cables) all at once, because unless you number them, they may become mixed up. Take a minute before you begin and number the wires with tape. The best location for numbering is near the ends of the wires.

NOTE: Apply a small amount of silicone dielectric compound (Ford part no. D7AZ-19A331-A or the equivalent) to the inside of the terminal boots whenever an ignition wire is disconnected from the plug, or coil/distributor cap connection.

- Twist the spark plug boot, then remove the boot and wire from the plug. Do not pull on the wire itself as this will eventually ruin the wire.

- If possible, use a brush or rag to clean the area around the spark plug. Make sure that all the dirt is removed so that none will enter the cylinder after the plug is removed.

- Remove the spark plug using either a 5⁄8 in. or 13⁄16 in. socket, depending on the engine. Turn the socket counterclockwise to remove the plug. Be sure to hold the socket straight on the plug to avoid breaking it, or rounding off its hexagonal wrenching surface.

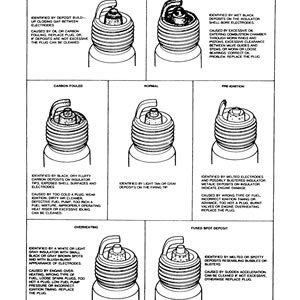

- Once the plug is out, check it against the spark plug diagnostic chart in this section to determine engine condition. This is crucial since plug readings are vital indicators of engine condition.

- Use a round wire feeler gauge to check the plug gap. The correct size gauge should pass through the electrode gap with a slight drag. If you are in doubt, try one size smaller and one larger. The smaller gauge should go through easily while the larger one should not go through at all. If the gap is incorrect, use the electrode bending tool on the end of the gauge to adjust the gap. When adjusting, always bend the side electrode. The center electrode is non-adjustable.

Fig. 1: Twist and pull the spark plug boot, not the wire

Fig. 2: Remove the spark plug using the correct size socket

Fig. 3: Spark plug diagnostic chart

Fig. 4: Checking the spark plug gap with a feeler gauge

Fig. 5: Adjusting the spark plug gap

Fig. 6: Inspect the spark plug to determine engine running conditions

-

Squirt a drop of penetrating oil on the threads of the new plug and install it. Do not oil the threads too heavily. Turn the plug in clockwise by hand until it is snug.

-

When the plug is finger-tight, tighten it with a socket. Torque to 5–10 ft. lbs. (7–14 Nm) for 4-cyl. engines or 10–15 ft. lbs. (14–20 Nm) for 6 and 8-cyl. engines. Take care not to over tighten.

-

Install the wire boot firmly over the plug. Proceed to the next plug.